- Products

- Hydraulic Vibratory Hammer

- Vibratory Hammer

- Power Pack

- Clamps

- Hydraulic Impact Hammer

- Impact Hammer

- Power Pack

- Excavator Mounted Vibratory Hammer

- Electric Vibratory Hammer

- Small Electric Vibratory Hammer

- Medium Electric Vibratory Hammer

- Large Electric Vibratory Hammer

- Tandem Vibratory Hammer

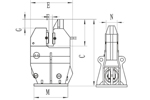

- Clamps

- Single Clamp

- Double Clamp

- Quaternion Clamp

- Control box

Electric Vibratory Hammer

- The small electric vibratory hammer can be divided into different types according to the pile driving force. Small electrical vibratory hammer bears smaller pile driving force. It consists of hammer, clamps and control box (motor needs to be allocated by clients). It adopts resonance theory and takes electromotor as its key component...

-

- The medium electric vibratory hammer makes use of resonance theory for designing. They are composed of hammer, clamps and power control boxs. They have different types according to motor power, such as DZJ120, DZJ135, DZJ150 and DZJ180 medium electric vibratory hammers. The electric motors provide energy for them and the motors work as key components...

-

- With the help of resonance theory, the large electric vibratory hammer is designed for various foundation engineering construction and ground treatment, such as the construction of dwelling houses, workshops, metros, highway, quays, airports and power stations, etc. Its energy is from the electric motor. Electromotor works as its key component. This electric vibratory hammer can drive cast-in-place concrete pile, lime pile and sand pile. Matched with corresponding clip pile device, this large vibrating hammer is capable...

-

- Yong'an electric tandem vibratory hammer is designed based on resonance theory. It is a pile hammer that obtains power from dynamo and takes electrical machine as core part. Its other names are: automatic hammer, vibratory hammer, piling hammer, pile driver, electric pile driver and electric pile hammer. It embraces hammer, clamp and control box. It is classified into DZJ480 electric tandem vibratory hammer and DZJ600 electric tandem vibratory hammer. This automatic hammer has been certified by ISO9001 Quality System...

-

- Clamp for vibratory hammer is employed with vibratory hammer in foundation constructions. According to the number of clamp head, this pile clamp can be divided into three models including single clamp, double clamp and X clamp. This clamp works very well in driving and pulling special casing piles, steel sheet piles and H beam piles. Besides, this pile clip can clamp precast piles as well...

-

Electric vibratory hammer is also named as electric vibrating hammer or electric pile hammer. It is designed with resonance theory. Electric motor provides energy for this vibratory hammer. And electromotor serves as its key component. It is the ideal equipment for various foundation engineering construction and ground treatment, such as the construction of dwelling houses, workshops, metros, highway, quays, airports and power stations, etc. When used in pile frame, electric vibratory hammer can drive cast-in-place concrete pile, lime pile and sand pile. Matched with corresponding clip pile device (namely hydraulic clamp), it is capable of driving and pulling a variety of steel piles and concrete pre-cast piles.

According to pile driving force, electric vibrating hammer can be subdivided into small electric vibratory hammer, medium electric vibration hammer, large pattern and tandem electric type.

1. Small Electric Vibratory Hammer (Widely Applied)

It can be classified into different models, such as DZ45, DZ60, DZ90, DZJ90 and X90 small vibratory hammer.

2. Medium Electric Vibratory Hammer (Widely Utilized)

It can be divided into various types like DZJ-120, DZJ135, DZJ150 and DZJ180 medium pile hammer

3. Large (Big) Electrical Pile Hammer (Can be used under special piling conditions like deep soil or hard soil condition. )

It can be subdivided into the following models--DZJ200, DZJ240, DZJ300 and DZJ400 big electric vibrating hammer.

4. Tandem Vibratory Hammer (Can be applied under special piling conditions like deep soil or hard soil condition.)

It can be spilt into two types-- DZJ480 and DZJ600 tandem electric vibratory hammer.

The electric vibratory hammer consists of a hammer, a clamp and a power control box. (Clients can allocate motor according to their actual needs.)

1. Yong'an electric vibrating hammer features high centrifugal force, high frequency and strong penetrating power to hard soil.

2. This electric vibratory hammer is installed with vibration damper which is equipped with weights. When pile driving, the large storage energy from the coil spring is capable of improving the efficiency of hammering. When pile pulling, good damping effect can be achieved and the pile frame can be well protected as well.

With custom designed concrete clamp, electric vibratory hammer can be used for various types of pre-made concrete piles, cast-in-place concrete pile, concrete expanded bore pile, lime pile and stone column pile.

2. Cofferdam

The electric pile hammer is used to drive sheet pile to build the coffer wall. It is high efficiency to drive and pull sheet piles.

3. Trestle Work and Offshore Working Platform

Drive sheet pile or casing pile to build working passage and platform before build bridge, dork, port, etc. It is easy to build and easy to remove.

4. Wind Mill Single Pile and Group Pile

It is efficient to use electric vibratory hammer drive casing pile into the sea, environmentally friendly and easy to adjust.

Clients should pay more attention to the centrifugal force, amplitude and eccentric moment. These parameters can tell the strength of an electric vibrating hammer. Meanwhile, different types of electric vibratory hammers have different requirements on corollary equipments (such as the power of motor and the tonnage of crane).

1. Electromotor of Electric Vibratory Hammer

(1) Please refer to the electromotor instructions.

(2) If the wire from connecting box is damaged, it should be wrapped with insulating tape and then be wrapped up with PVC tape. If the wire is serious damaged, it should be replaced.

(3) Users should check whether the screw between electromotor and the tank is loose. If the screw is loose, it should be fastened so as not to damage the electromotor.

(4) The screws on belt pulley pressing plate should be fastened. If they are damaged, the screws should be replaced.

(5) Refill the main motor bearings.

(6) If the temperature rise in electric motors exceeds the allowable value, the machine should stop. After troubleshoot, the electric vibratory can work again.

2. Electric Vibratory Hammer Host

(1) When filling vibrating hammer, the tank should be erect and the refilling oil shouldn't be too much. It is OK when the refilling oil reaches the red point of the oil level indicator. Calcium base grease should be refilled between vertical axis and nylon bushing.

(2) When refilling the tank, (after 40 hours for the first refilling and 300 hours for afterward refilling) the drain plug at the bottom of the tank should be detached so as to let out the original oil. And then open the flank, remove the greasy dirt, dust and left powder of metals and screw up the drain plug, add fresh oil into the tank.

(3) All kinds of screws and nuts should be checked as often as possible. If they are loose, fasten them. If they are damaged, replace the screws and nuts.

1. Shatter-Proof Electromotor

The electromotor of Yong'an electric vibratory hammer adopts is of high acceleration. And the allowable maximum temperature in its bearing can be as high as 95 degree centigrade. Besides, the electric vibratory hammer employs high tenacity v-belt. And it features short time overload use and high starting moment.

2. Bearings

This electric vibrating hammer takes the advantage of X-LIFE high quality series bearings of brand FAG from Schaeffer Group in Germany. X-LIFE indicates that this series of bearings can undertake another 18% load capacity. Therefore the working life of electric vibratory hammer can be increased by 70%.

3. Product Process

The whole welding process of the electric vibratory hammer conforms to national level welding standards. It adopts ultrasonic flaw detection. Besides, all round of the bottom half makes use of wrap angle. And the strengthening rid can efficiently reduce the stress of the tank. When working, the damage to the tank can be reduced to the minimum and the working life of electric vibratory hammer is prolonged.

4. Noise Proof Design

First, sheet rubbers are added to the base of the up and down springs. The sheet rubber has buffer effect and can absorb certain noise generated during the working process. Second, sound insulation plate is also added up to the bottom spring and this can effectively lower the working noise of the electric vibrating hammer.

5. Unique Bearing Collar Design

Compared with the traditional bearing collar, Yong'an electric vibratory hammer adopts the most advanced cutting technology for bearing collars, so such bearing collars are not easy to result in cracks and the whole equipment can work stably, and at the same time, this design guarantees the service life of the electric vibrating hammer.

6. Oil stain deposit system

We developed oil stain deposit system, which could avoid the damage to the gear and bearing.

30% deposit payment should be paid after signing the contract. Full payment should be paid before delivery.

Electric vibratory hammer and clamp adopt thin film packaging. The control cabinet and components can employ wooden case packing (according to clients' requirements).

Established in 1986, Shanghai Lanteky® Machineis a professional maker of electric vibratory hammers in China. And with 27 years development, we have accumulated rich experience in the manufacturing, selling and utilizing electric vibrating hammers. We are capable of providing all-round service for every customer, from pre-sale technology consulting to after-sale application. We are constantly committed to technology innovation and development of products. Shanghai Yong'an is engaged in traditional DZ, DZJ series electric vibratory hammers. With ISO9001 quality system certification and independent innovation, we have manufactured various new series electric vibrating hammers (such as DZJ-400, DZJ-480 and DZJ-600 tandem vibratory hammer ) so as to meet different needs of working conditions.